designboom visits LAUFEN's design development team, who work with new pieces from their first conceptualization through mold-making and prototype analysis as a design is prepared for production

above, jannik stöckli, an industrial ceramics apprentice, sands down a cast to meet technical specifications

image © designboom

designboom had a behind-the-scenes look at the LAUFEN ceramics factory, where we had a manufacturing tour of the

swiss company's fabrication process. we've documented the many steps and design considerations that go into the production

of bathroom fittings, offering a better understanding of the different design criteria and production methods required for these

everyday household pieces, as well as the way in which such an ancient material as ceramic is being utilized in high-tech

and industrial applications in the present day.

in this article, part of a longer behind-the-scenes series, let's get back to the very beginning of the life of a ceramic piece

by looking at the design development process. by far the most time-intensive stage of production, this process takes about

a year for each new design, from the first idea and briefing through when the piece is on the production lines. LAUFEN is

particularly esteemed in the design world for its collaborations with renowned industrial designers and architects towards

the creation of bathroom pieces. here the process can differ in its particularities: sometimes designers are approached to develop

new product lines, other times individuals submit ideas to LAUFEN in response to a product briefing, in which case the selection

of a designer and piece becomes part of the development process. anytime the company works with a new collaborator,

(s)he is invited to spend time in the factory learning a bit more about the methods and particularities of working with ceramic;

oftentimes these designers move on to engage in longer-term collaborations with the company.

marc viardot, director of marketing and products

looking more generally at the company's design philosophy, LAUFEN routinely conducts worldwide research surveys

to maintain a forward-looking perspective, asking architects, interior designers, and retailers to identify current trends

in bathroom culture, and report on the needs and desires expressed by consumers. while the research doesn't exclude

physical attributes such as colour or silhouette, LAUFEN is increasingly finding the focus on what marketing and products

director marc viardot terms 'wellness 2.0', the seamless integration of functionality and aesthetic as they affect an individual's

experience, within the greater context of a home.

ultimately, however, a successful concept depends on successful execution, and in order for any proposed piece to continue on in

the LAUFEN design process, it must pass a rigorous 'visibility analysis' in a team meeting of the plant manager and supervisors

in the casting, glazing, and firing departments. here, these professional craftsmen examine a design to ensure that it can be

produced within the constraints that the ceramic material and production process defines.

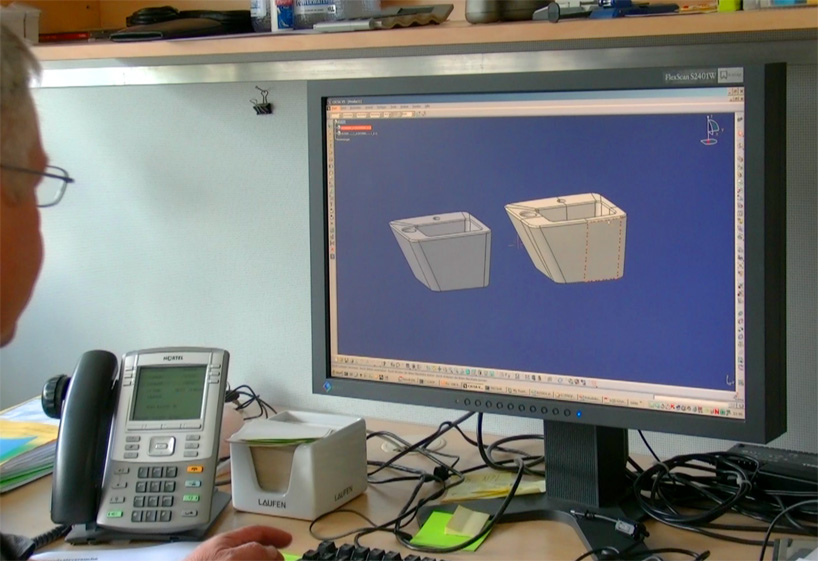

the design development team works with products from the first ideas stage, through design selection, mold-making, and prototype analysis and reworking

image © designboom

to maintain a forward-looking perspective, asking architects, interior designers, and retailers to identify current trends

in bathroom culture, and report on the needs and desires expressed by consumers. while the research doesn't exclude

physical attributes such as colour or silhouette, LAUFEN is increasingly finding the focus on what marketing and products

director marc viardot terms 'wellness 2.0', the seamless integration of functionality and aesthetic as they affect an individual's

experience, within the greater context of a home.

ultimately, however, a successful concept depends on successful execution, and in order for any proposed piece to continue on in

the LAUFEN design process, it must pass a rigorous 'visibility analysis' in a team meeting of the plant manager and supervisors

in the casting, glazing, and firing departments. here, these professional craftsmen examine a design to ensure that it can be

produced within the constraints that the ceramic material and production process defines.

the design development team works with products from the first ideas stage, through design selection, mold-making, and prototype analysis and reworking

image © designboom

this design engineer is simultaneously viewing the dimensions of a piece pre- and post- firing in the kiln

image © designboom

finalized designs become technical diagrams that workers use as they measure and optimize early run prototype models

image © designboom

once a particular design has been accepted as a good candidate for production, the piece must first be clearly outlined with a technical diagram,

in conjunction with quality assurance tables on all dimensions and acceptable tolerances in measurements. these will continue to be of importance

throughout the next several stages of prototyping, as the piece is reviewed and inspected at multiple points.

in the development offices of the LAUFEN factory, designers take on the first steps of prototyping, working with 3D modeling software

to draft new pieces, with an eye towards not only the exterior aesthetics but also the ways in which the interior will permit successful connection

with necessary piping. in particular, because different countries have different piping and drainage standards as well as different legal regulations,

every design must be adaptable to meet the codes of all countries in which it is planned to be sold. the designers note that practical testing of prototypes

after firing remains an extremely important part of the process, but they can already begin to efficiently design models for success by working first

in 3D sketching environments. this software is also particularly helpful to generate and compare the dimensions of models before and after firing

(whereupon they shrink).

the design and development workroom

image © designboom

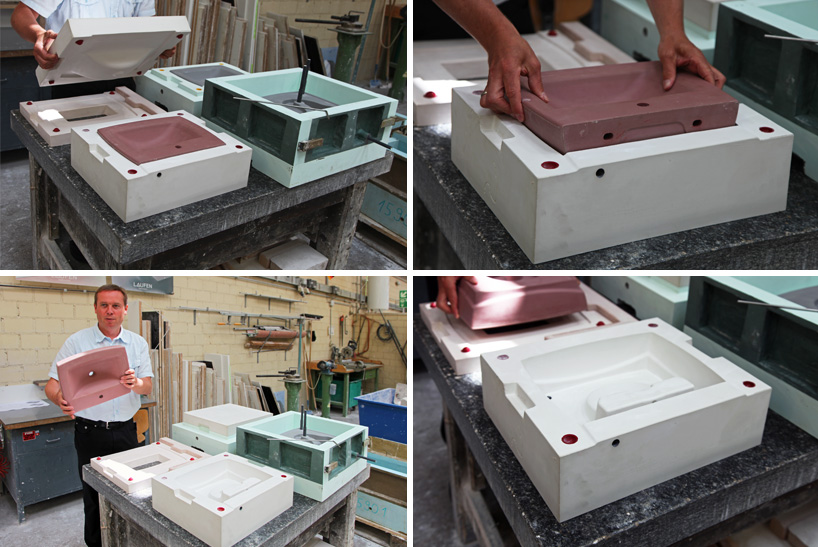

from the design and development offices, we head next to the model shop, a long, brightly skylit room whose evenly spaced worktables

are covered with models and ceramic casts. along the sides of the room, individual workstations include specialty tools, work notes, and the

occasional personal object, from soccer flags to living plants. it is here that the first 1:1 scale prototypes are produced. the first, one-off piece

of a design-- the 'CNC model'-- is produced by an external company and shipped to LAUFEN, where craftsmen first create a plaster "model mold",

from which they cast the first in-house prototype. molds vary in complexity from two pieces for most washbasins, to many internally fitted

small parts to create the holes and interior architecture of more complicated designs like toilets.

rubber mold and plaster cast

image © designboom

profile view of one piece of a mold, with engineering notes marked on the plaster cast visible behind it

image © designboom

the first one-off edition of this small basin (reddish colour) is used by LAUFEN to generate the plaster 'model mold' whose use is demonstrated here

images © designboom

workstations along the edges of the room provide space for workers to carefully measure and work with early models

image © designboom

in this space, craftsmen are also working with prototype casts to notate by hand any necessary corrections for deformation caused

by shrinkage during firing. this is just one of several ways in which it is evident that review and optimization remain a part of the design

process from the first inkling of a new concept through to the shipment of completed pieces; ceramic is a natural material, and so designers

must think carefully about the properties and limits of the material as they conceptualize their works. although LAUFEN's precise methods

of testing the ceramic slip material ensure that all production line pieces are being formed from uniform, high-quality ceramic, the process

of molding the first few prototypes of a new line can sometimes highlight unexpected behaviour of the material as it interacts with the shapes

and points of tension of the designed form.

as a result, the first prototypes of a series are produced on the LAUFEN factory floor, but are each examined in the model shop,

where measurement corrections are marked by hand on the piece. from these calculations, the model mold is then altered.

through this process, often up to three to five prototypes are created before the results meet LAUFEN's strict technical standards

and tolerance restrictions.

image © designboom

craftsmen must measure carefully to make sure that prototype casts represent the precise dimensions and forms specified in their technical sheets, and did not suffer deformation during firing

image © designboom

additional view of workspace as a piece is being measured and carefully modified with the hand tools seen on the table to meet design specifications

image © designboom

closer view as jannik stöckli, an industrial ceramics apprentice, sands down a cast to meet technical specifications

image © designboom

once the prototype casts are coming out properly, LAUFEN creates the case mold, composed of plastic and rubber (enabling the release of ceramic

casts once they have dried), and then the pressure-casting mold if one is being used in this product line. finally the first pilot series can be produced,

also through regular methods on the production floor. at least 20 pieces are formed, glazed, and fired, before undergoing close inspection to ensure

that the casting techniques have successfully translated to higher quantities.

if it has, each future piece is still subject to the strict quality controls that LAUFEN puts on every object produced in its factory, but the line has

successfully entered the production phase.

raw materials used in the creation of ceramic are also housed in the development and prototyping workspace

image © designboom

alberto magrans, senior managing director, on the challenges of working with ceramic and the innovative potentials of the material that the company is currently pursuing

No hay comentarios:

Publicar un comentario